Chain Systems

The basis for resistant conveyor belts.

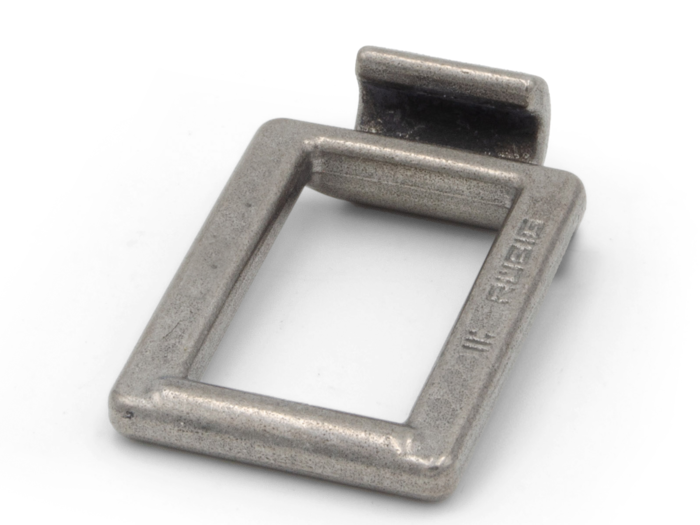

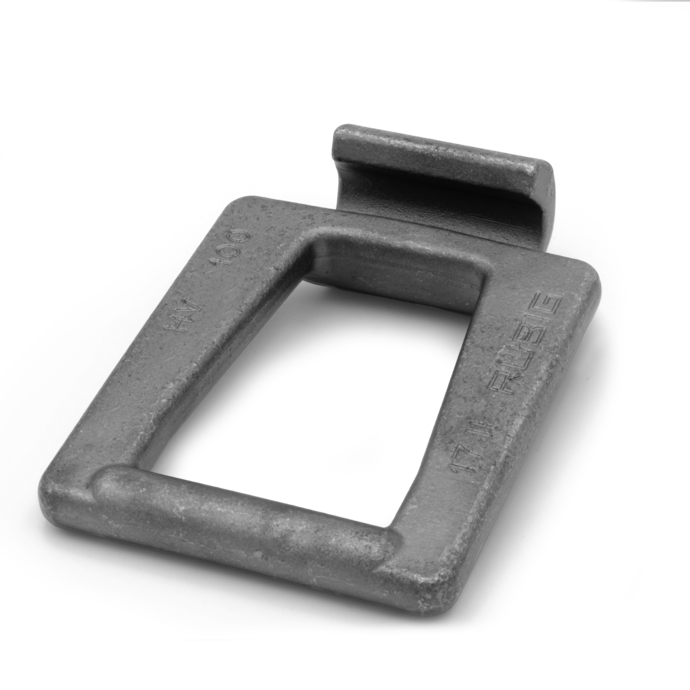

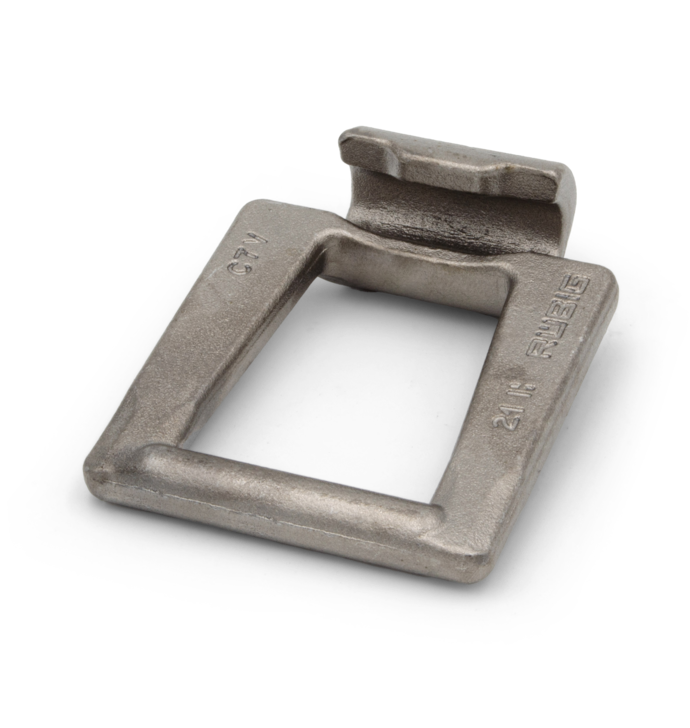

They are stand out through their impressive wear resistance, hardness and toughness. These chains are also often referred to as flat link chains or simply flat chains. Another advantage: they can be easily welded and assembled individually.

RUBIG chains are the first choice for countless applications – from screen cleaning of smaller hydroelectric power plants to shredder plants, from beet harvester to silo cutter and manure spreader.

The ideal chain for rough operation. In addition to its construction, a particularly favorable fiber and microstructure is the basis for its high breaking load. Insensitive to weather influences, wear-resistant, easy to weld and can be disassembled by hand. You can find more details in the Shoplink.

The "C" series is a further development of the proven RUBIG chain system. In addition to the well-known advantages, it offers, among other things, an extended service life: the new hook shape prevents independent unhooking even after advanced wear and during reversing operation. More details can be found in the shoplink.

The extremely strong RUBIG heavy duty chains are forged from boron alloy steel as standard. Large articular surfaces reduce wear and elongation. Attachment plates, cross bars, etc. can be welded directly to the chain links. Extended chain bolts are a cost-effective alternative as a fastening option. More details can be found in the shoplink.

RUBIG also supplies the gears matching the chains. Thanks to their special tooth shape, they ensure smooth running, low wear and reliable power transmission – even after longer running times. Available as sprocket blanks and as finished machined sprockets. More details can be found in the shoplink.

The RUBIG chain can run in both directions. If the chain will be soiled it is better if the flap points in the running direction (A). In the case of high tensile forces (at the latest when 20% of the breaking load has been reached), the chain should be installed in reverse (B), so that the chain links detach more easily from the drive wheels. Be sure to place the chain on the sprocket with the open side of the flap facing outwards! If possible, the drive should be arranged on the pull side / in the desired (main) conveying direction

Not the standard, but your solution: RUBIG Chains, designed to meet the highest demands. Our sales consultant will show you how you can excel with quality.

Head of Sales