Industries

From classic components to lifestyle and medical devices: RUBIG know-how can be found in many industries.

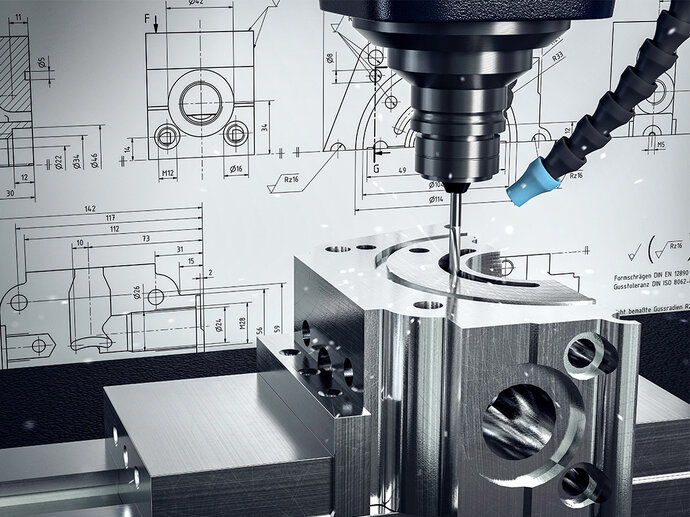

A passenger car consists of up to 10,000 components. Whether shafts, valves, cylinder heads, bearings and much more: they all maintain their corrosion resistance, wear resistance and individual properties through RUBIG heat treatment and coating processes. Our processes impress with precision, the tightest tolerances and the highest surface qualities. Well-known automobile manufacturers and representatives of drive technology rely on us. Upon request, we can also provide you with the appropriate furnace.

In the aviation industry, the highest precision and complex geometries are essential.

The requirements are enormous, as complex materials and minimal temperature differences must be taken into account at all times – exactly the specialty of our aviation-certified MICROPULS® plasma nitriding systems.

At RUBIG, heat treatments can be carried out according to the following standards:

Surgical and dental instruments, prostheses and splints are just a few examples of medical technology that contains RUBIG technology. The industry is characterized above all by the close integration of products and services and a continuously high level of research and development activities. In the field of vacuum hardening, we are MDSAP certified and our coating systems are characterized by good biocompatibility.

Thanks to RUBIG MICROPULS® or GASCON systems, the two main requirements of the industry can be perfectly met: wear and corrosion resistance. We can also create weakly reflective, black surfaces using coatings. This not only ensures reliable protection, but also meets all aesthetic requirements.

The toolmaking industry can benefit from the advantages of the RUBIG DUPLEX process, which enables thin compound layers with flexible adjustment and increased surface hardness. Another option is MICROPULS® Procoat TiN coatings. With these innovations, tools become even more resistant and durable.

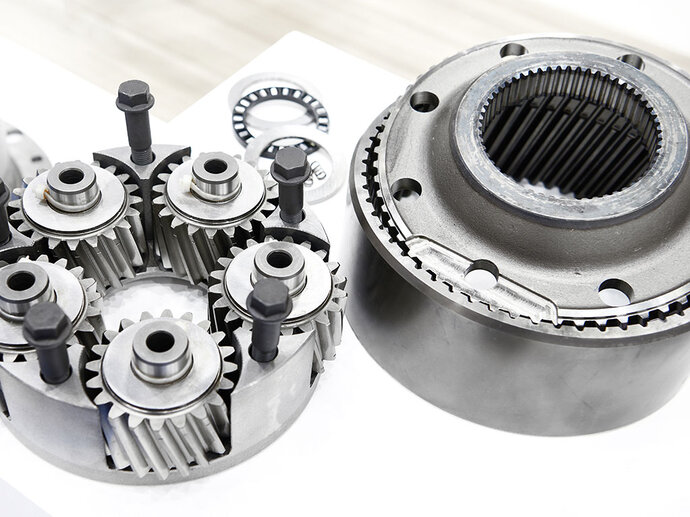

RUBIG systems can improve the breaking strength, which leads to less damage and accidents. This makes workpieces such as gears, shafts or tools more resistant and reliable. The RUBIG MICROPULS® technology can thus not only increase safety, but also increase productivity and reduce costs.

Behind every wind power plant there is an enormously stressed drive technology. With RUBIG MICROPULS® technology, drive components are designed for the highest precision requirements as well as different loads. The meter-sized components must not only withstand high material stresses, but also have a minimal distortion.