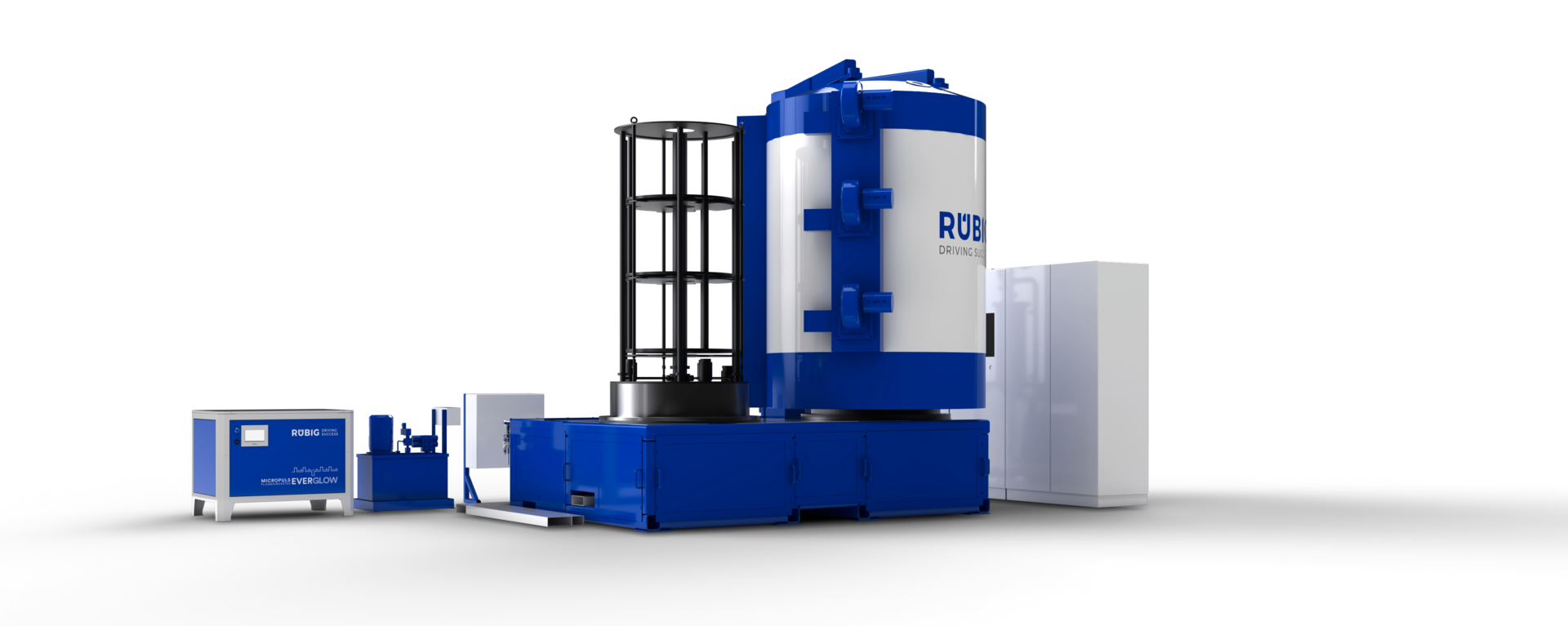

With the MICROPULS® Diamond Xtended, RUBIG delivers one of the most innovative system solutions in the field of DLC coating technology.

The DLC Xtended® process offers more than just DLC: low treatment temperatures result in almost no dimensional changes. Post-processing and mechanical covering are eliminated, which saves time and money.

The coating can be adapted to any requirement, regardless of the size, geometry and complexity of the components, even three-dimensionally without rotation. No toxic gases are used.

Customers from the field of hydraulics, defense or drive technology trust our expertise in industrial furnaces. You can do so as well and benefit from numerous advantages!

| Type | Useful diameter | Useful height | Maximum batch weight |

|---|---|---|---|

| DIA 70/120 | 700 mm | 1.130 mm | 1250 kg |

| DIA 100/180 | 850 / 1.000 mm | 1.650 mm | 5000 kg |

| DIA 150/240 | 1.300 / 1.500 mm | 2.330 mm | 7500 kg |

All systems are available as SINGLE, DUO or TANDEM systems, as well as laboratory or special sizes.

Innovative and Tailor-Made

With over three decades of technological leadership, we develop equipment solutions precisely tailored to your manufacturing processes. Consult with our experts to implement a solution that sustainably optimizes your production.

DI Stefan Haas

Head of Sales

PROCESS

With the MICROPULS® Diamond Xtended, the DLC Xtended® process is realized.

Learn more about the DLC Xtended® process here!