Die forge

We have been forming steel for over 70 years.

Franz Rübig & Söhne Gesenkschmiede (Die Forge) was founded in 1946 and is the parent plant of the RUBIG Group. For decades, it has stood for innovative solutions, from the blank to the ready-to-install serial part, which are developed together with the customers.

As a competent partner for innovative manufacturing solutions, we are constantly working on technical improvements, using rationalization potentials and expanding our product range.

At RUBIG, everything comes from a single source. From the forged part to the ready-to-install, i.e. mechanically machined, surface-finished, welded and, if necessary, assembled part, RUBIG is your competent partner. You can also count on the experience and creativity of our experienced employees to realize the development and testing of your parts.

Before a new forged part can be produced, the necessary tools must be manufactured. The design alone determines the quality and cost-effectiveness of the part. RUBIG’s computer-aided design solutions are always created in close coordination with the customer and our in-house tool shop. The required milling programs are derived directly from the 3D design, resulting in precise shapes, without delays during hardening or transfer errors. The heat treatment is conducted at our state-of-the-art sister company, RUBIG Heat Treatment. All information, tools, and forgings remain in-house, ensuring absolute confidentiality of new developments.

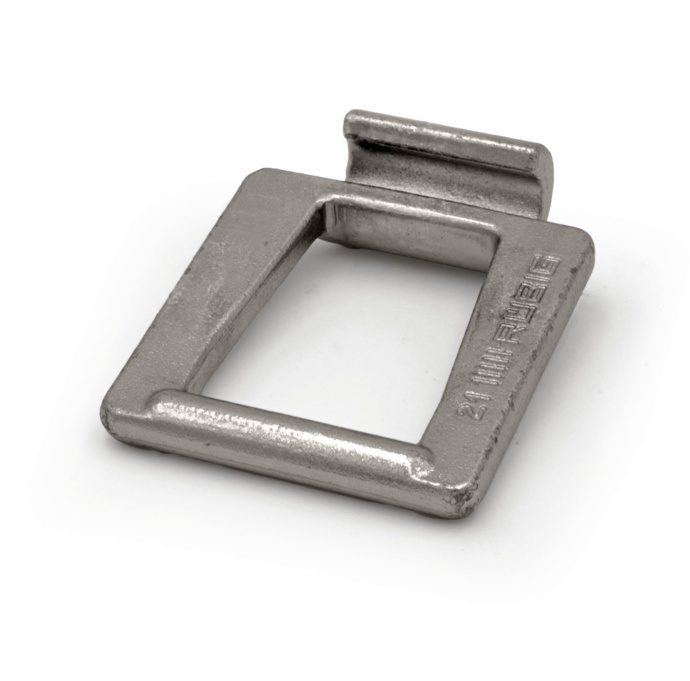

Whether for three-point tractors, truck cranes, construction machinery, wheel or nut securing, or in formwork technology, RUBIG offers the optimal linchpin for numerous applications. We have more than 80 different types and sizes of linchpins available.

RUBIG chains are the first choice for countless applications—from screen cleaning in smaller hydroelectric power plants to shredder plants, and from beet harvesters to silo cutters and manure spreaders. The matching sprockets ensure maximum quality

Our die forgings are optimized in both form and function, offering economic flexibility. Our processed materials range from simple structural steel to case-hardening and tempering steels, and even to stainless steels.

Sandblasting, machining, welding, tempering, grinding, fluxing, and pressing: Our comprehensive range of services completes our offering.

RUBIG crafts exclusive hunting knives and eco-friendly fishing accessories made from steel.

How can we help?

We are happy to advise you personally. Contact us and get detailed information about the products you are looking for!

RUBIG sets standards in the agricultural industry with innovative forging, drive, and conveyor technologies. Our durable, die-forged parts range from robust tools and versatile linchpins to high-strength machine components, each specially developed to meet the challenges of modern agriculture. Through our expertise in machining and surface finishing, we enhance both the efficiency and durability of your equipment.

In engine manufacturing, RUBIG provides high-precision forged parts and services, ensuring optimal performance and reliability. From crankshafts to connecting elements, our products extend engine lifespans and support innovative drive technologies. Our comprehensive machining and heat treatment processes produce components that meet the highest industry standards.

RUBIG's advanced forging and machining technologies propel mechanical engineering forward. Our custom-forged parts and precise machining solutions enhance both the performance and reliability of machinery and equipment. With innovative drive and conveyor techniques, alongside our expertise in fastening technology, we secure your industry leadership.

For the demanding recycling industry, RUBIG supplies exceptionally durable and wear-resistant forged parts. Our services, including sandblasting and specialized heat treatments, enhance the efficiency of recycling facilities and reduce operating costs. RUBIG represents innovation and sustainability in material processing.

RUBIG enhances vehicle technology with cutting-edge forging and machining solutions. Our components for chassis and drive systems establish new benchmarks for safety and performance.

As a traditional family business, RUBIG is committed to thinking long-term and fostering sustainable business relationships. This commitment requires continuously meeting customer expectations, a goal achievable only through impeccable product quality and perfectly organized processes, time and time again.