NEWS

Current news, trade fairs and important developments: With our news page you are always up to date.

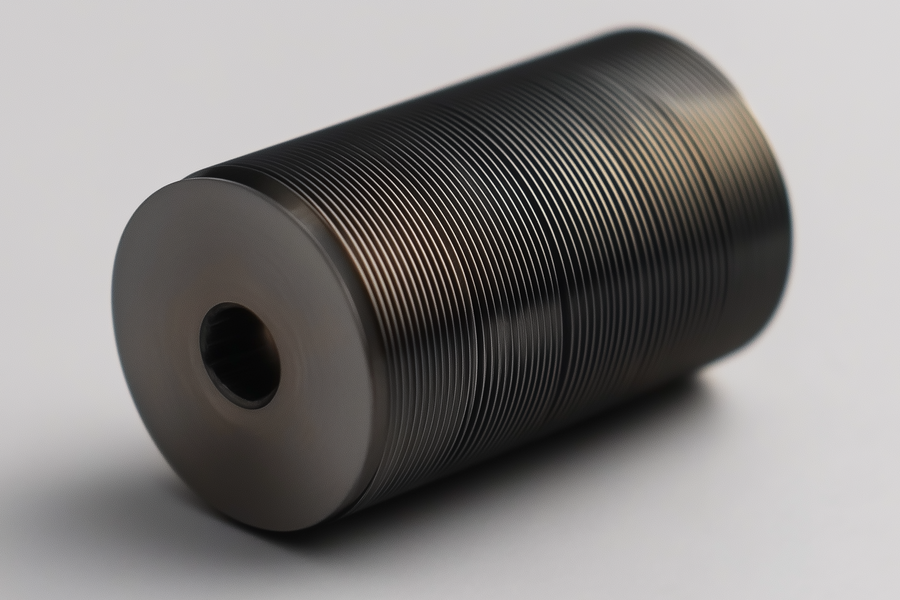

Thread rolling tools are subjected to extreme stresses, and every failure has financial implications. Plasma nitriding is an innovative surface hardening process that specifically reduces wear and significantly increases the service life of your tools. The process is precise, low-distortion, and environmentally friendly – making it ideal for demanding cold forming applications such as thread rolling.

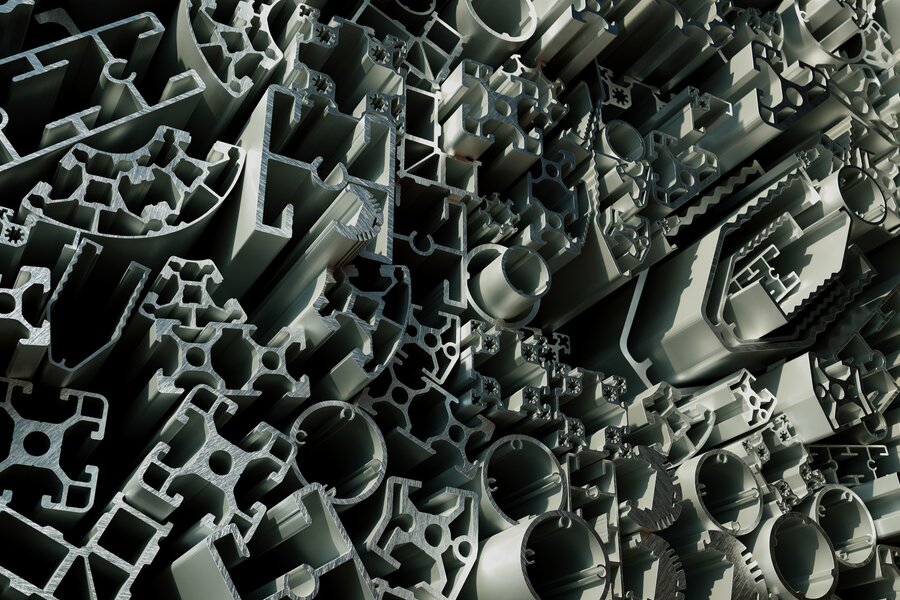

Aluminum extrusion presses aluminum alloys through tools to form complex, lightweight profiles. Thanks to their low density, corrosion resistance, and excellent formability, they are essential in the automotive, mechanical engineering, electrical engineering, and aerospace industries.

In January 2025, other important heat treatment processes were NADCAP-certified.

An interview with Sebastian Walchshofer, Head of the Automation and Software Department at RUBIG Industrial Furnances.

At the end of 2024, the RÜBIG Group will restructure its management: Bernd Rübig will assume joint leadership with Christian Dipolt,

Technology, man and machine are an unbeatable team! With the RUBIG visualization, these three success factors merge into an ultimate tool for your RUBIG system and transform effective processes into highly efficient processes.

Whether in the automotive, aerospace or mechanical engineering industries, they all benefit from the excellent tribological wear protection of WC/C-DLC coatings.

RUBIG enters new dimensions of surface treatment and offers innovative deep black coatings. With an L value of less than 30 in the L.A.b color space, the deep black coated components look as if they were absorbing the light.

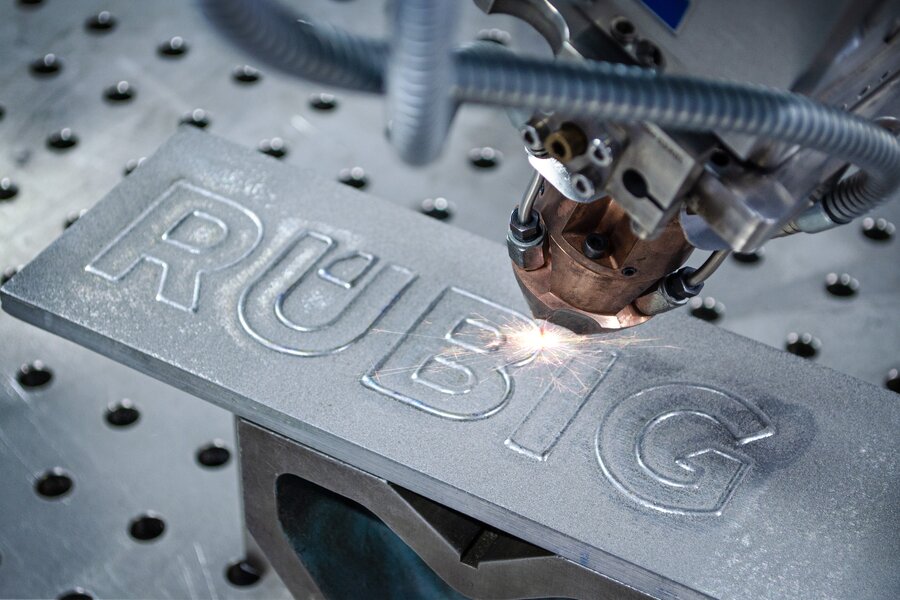

Cost and energy efficient: Laser deposition welding and laser hardening give your components the properties they need.

Deep nitriding in Aerospace is not only technological top class, but rather an art in its own right.

The RUBIG AntiViralCoating based on copper or copper oxide is intended to reduce or even prevent the spread of viruses and bacteria through oxidation of the surface. It is suitable for metal, plastic and filter materials.

OEMs and suppliers in the pharmaceutical industry see themselves confronted with engineering challenges of making production steps more efficient while keeping high quality levels.

Linchpins are fastening elements that serve as securing elements on agricultural machines, construction machines or commercial vehicles, to name just a few.

What exactly happens during plasma nitriding?

Surgical instruments are exposed to extreme environmental conditions when in use and still have to fulfill the highest quality criteria in terms of hygiene. Technological advancements have led to a substantial progress in providing the latter.