NEWS

Current news, trade fairs and important developments: With our news page you are always up to date.

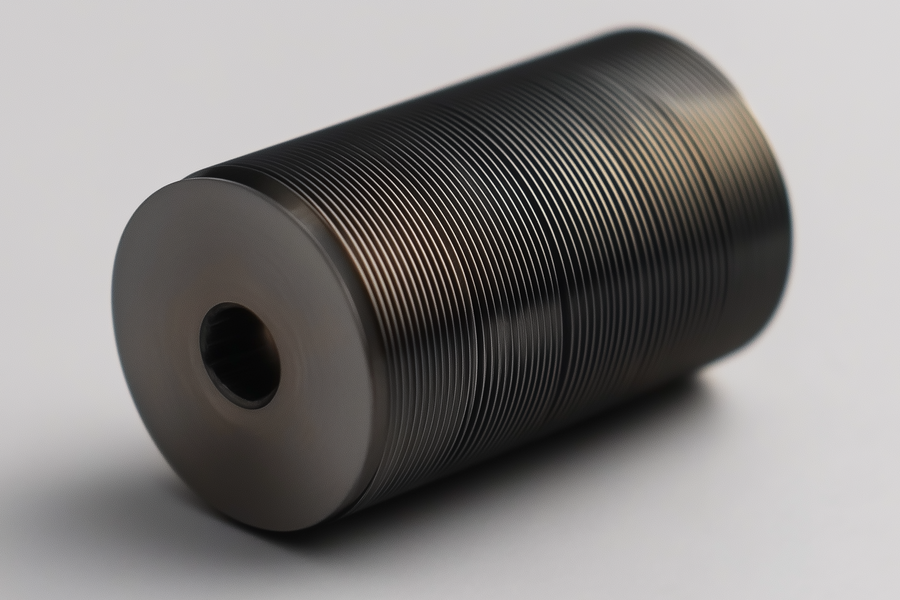

Thread rolling tools are subjected to extreme stresses, and every failure has financial implications. Plasma nitriding is an innovative surface hardening process that specifically reduces wear and significantly increases the service life of your tools. The process is precise, low-distortion, and environmentally friendly – making it ideal for demanding cold forming applications such as thread rolling.

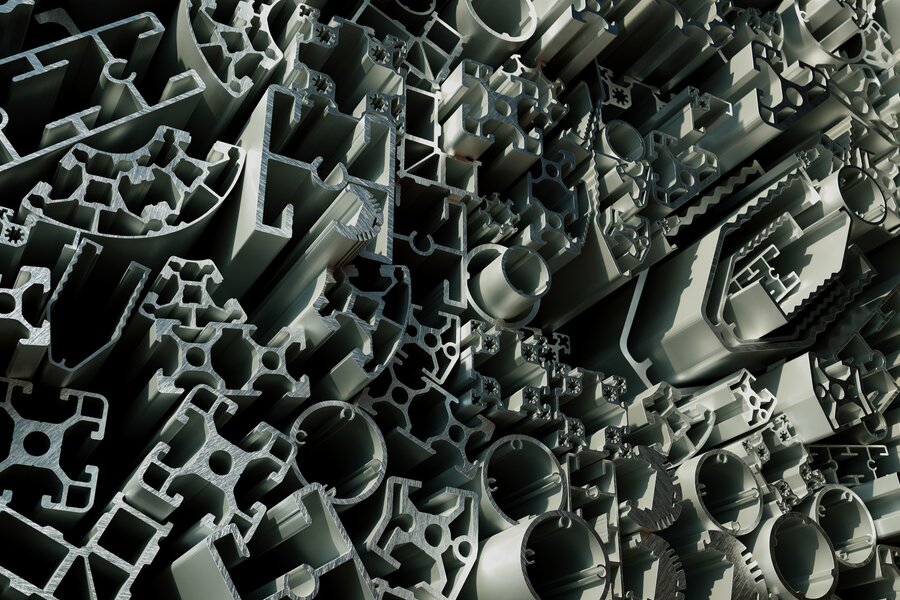

Aluminum extrusion presses aluminum alloys through tools to form complex, lightweight profiles. Thanks to their low density, corrosion resistance, and excellent formability, they are essential in the automotive, mechanical engineering, electrical engineering, and aerospace industries.

In January 2025, other important heat treatment processes were NADCAP-certified.

An interview with Sebastian Walchshofer, Head of the Automation and Software Department at RUBIG Industrial Furnances.

At the end of 2024, the RÜBIG Group will restructure its management: Bernd Rübig will assume joint leadership with Christian Dipolt,

Technology, man and machine are an unbeatable team! With the RUBIG visualization, these three success factors merge into an ultimate tool for your RUBIG system and transform effective processes into highly efficient processes.

Whether in the automotive, aerospace or mechanical engineering industries, they all benefit from the excellent tribological wear protection of WC/C-DLC coatings.

RUBIG enters new dimensions of surface treatment and offers innovative deep black coatings. With an L value of less than 30 in the L.A.b color space, the deep black coated components look as if they were absorbing the light.

Cost and energy efficient: Laser deposition welding and laser hardening give your components the properties they need.

The RUBIG Aluminum in Pilsting was officially opened on 28 September in the presence of numerous customers, friends and employees of the RUBIG Group.

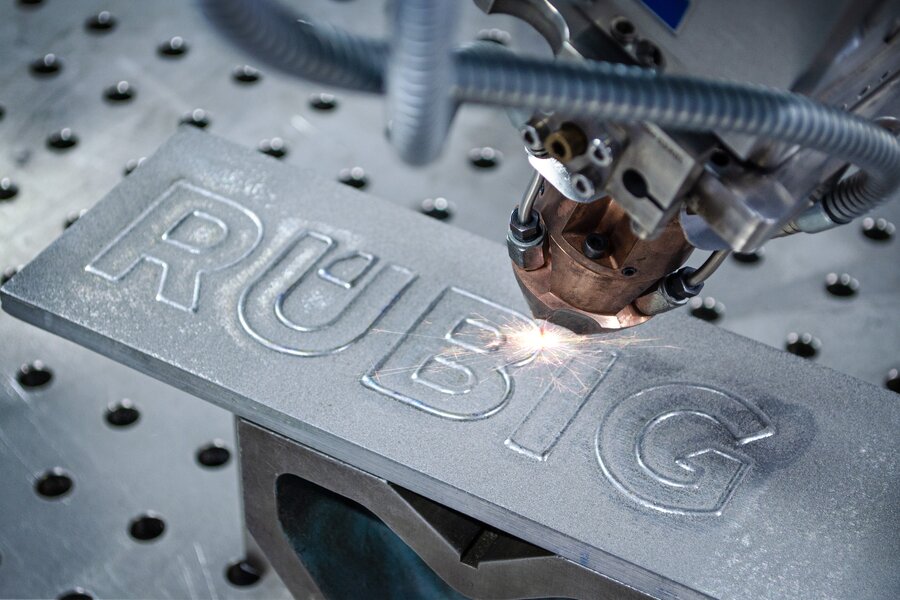

Since this summer, the RUBIG Materials engineering laboratory has the possibility of state-of-the-art and precise laser marking of components and samples made of metallic materials (steel, aluminum, etc.) and plastics.

The interaction between the die forged bolt and the spring bracket - especially developed for each type and size - is of particular importance in RUBIG linchpins and their safety.

The daily orders via the RUBIG Online Shop range from a very small quantity of special linchpins, to large orders to individual spare parts.

WELS: RUBIG Industrial Furnaces produces plasma and gas nitriding systems for customers worldwide.

WELS/TAICANG: Sustainable growth is the focus of the internationally successful RUBIG Group.